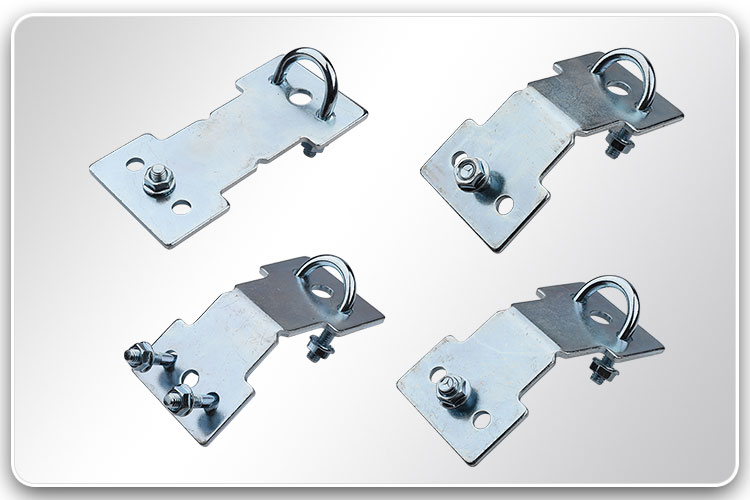

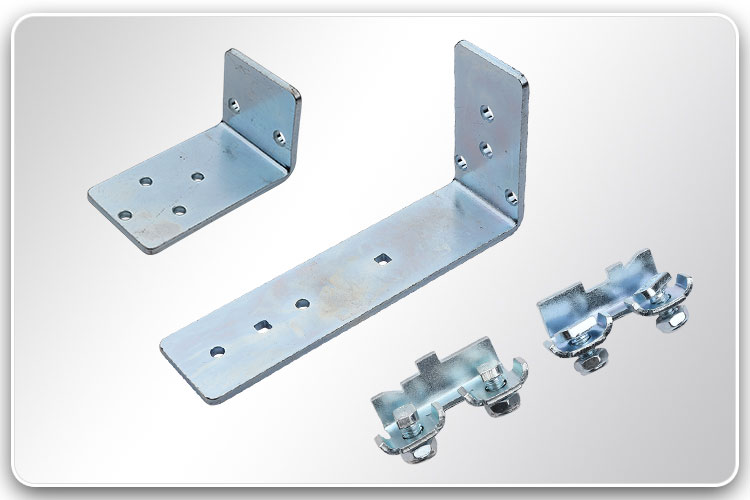

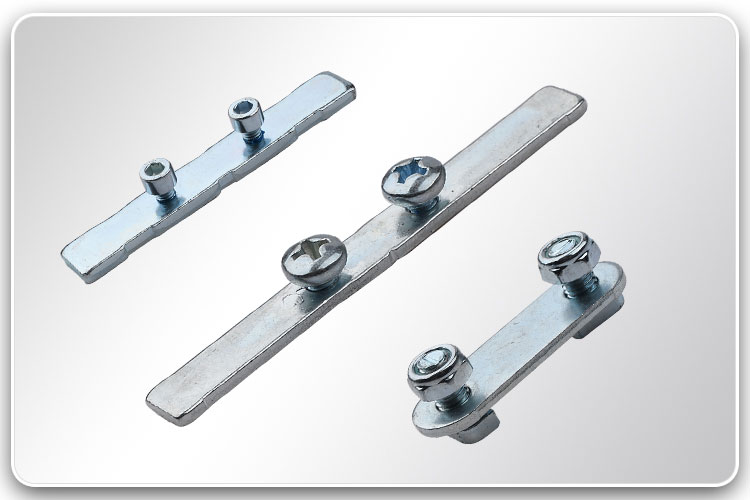

This Garment Logistic Racking parts we developed for a German client 5 years ago. The special requirement for this particular product series is the welding nut needs to undergo strict torque test, there is a unique requirement for the thread glue . The bolt with thread glue needs to be imported from Germany or, the parts to be assembled at our partner’s warehouse in Germany.

Big order quantity, high quality requirements, reasonable inventory for on-time delivery are the basic requirements from the client, and price needs to be extremely competitive. This series orders are of big challenge for Auwell, as for the big price pressure and inventory requirements, it is required supplier has perfect production plan, strict quality management and effective cost organization, also strong financial capability for inventory management.

The process of Garment Logistic Racking Parts includes 5 steps - cutting, forming, welding, surface treatment and assembling.

-Leikkausprosessi

For this Garment Logistic Racking Parts, the stamping is the most common way for material blanking.

-Forming Process

Muovausprosessi sisältää tyypillisesti taivuttamisen, lävistämisen ja jauhamisen. Osien suunnittelun luonne määrittää käytetyn menetelmän. Purseenpoisto on välttämätön toimenpide ennen hitsausta ja kokoonpanoa.

-Kokoonpano

Vaatteiden logististen telineiden osien tärkein kokoonpanoprosessi on hitsaus ja ruuvaaminen. Valaisimet on suunniteltava ja valmistettava siten, että varmistetaan, että tuote ei vääristy hitsauksen jälkeen. Joukko testimittareita on kehitetty laaduntarkastusta varten, mikä varmistaa tuotteen täydellisen toimivuuden.

-Surface Treatment

So far, only zinc-plating surface treatment for this series of products. Other surface treatment including electrophoresis (KTL), powder coating, painting is available upon request.

Technical Specifications

-Materiaali

SPHC-teräslevy, korkealaatuinen kiinnitin

-Pintakäsittely

Zinc plating

-Muut eritelmät

Capable in designing and developing necessary tools for Garment Logistic Racking Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Pintakäsittely includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production.

Edut

-Rich Experience

More than 5 years of experience in Garment Logistic Racking Parts development and production, especially to the European markets, with solid understanding of the material, technical and quality standards worldwide.

-Nopea käännös

Tarjoamme tarjouksen yleensä 3 työpäivän kuluessa. Yhdistämällä uusimmat valmistustekniikat ja -laitteet Auwell voi tarjota nopeita prototyyppejä vain 3 viikossa yksinkertaisille projekteille.

-Kattava ratkaisujen tarjoaja

Auwell provides comprehensive services for Garment Logistic Racking Parts starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-Jäykät laadunvalvontapolitiikat

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection to Garment Logistic Racking Parts orders. Materiaali certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Joustava maksuehto

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

The following catalogues of Garment Logistic Racking Parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик